We are a company that does printing and we diecut a lot of our material. Currently, we have our dies listed in the Resource Group but only by name and dimensions. We are wanting two things. 1) Does anyone on here work with diecutting and tracking of what dies you have, and 2) is there a way to basically turn the die list in Resource group maintenance into a link of sorts to show a JPG of the die? There are subtle differences in our dies and sometimes we buy the same one multiple times due to just not knowing if we have the die or not. so trying mitigate this issue.

Will,

We use molds in my business. We do it a little funky by making the mold a part on the bom instead of resource. It had to do with the limitations on co-parts as I’m told.

The short answer to your question is yes, you can absolutely display pics for your resources. It requires some customizations but it’s not overly complicated. If you have any experience with c# it’s not too horrible - if you don’t have experience you can hire a consultant to do it for you.

I wonder if you could switch the Attachements functionality ON. you used to do the same with change Log in Epicor 9. Otherwise would be looking for a creative solution / work around. Attachments functionality is intrinsic when the BO is generated.

private static void AbcCodeForm_Load(object sender, EventArgs args)

{

ChangeLogHelper changeLogHelper = new ChangeLogHelper(AbcCodeForm);

changeLogHelper.AddViewToWatch(oTrans.EpiDataViews[“AbcCode”] as EpiDataView);

}

I would have a UNC path and a standard naming convention combined with an EpiPicture Box maybe…

@Chris_Conn That is interesting. Never thought of the BOM instead of the Resource. Are there any other disadvantages? Mostly curious. Not sure If I want to use the BOM. But always interested in how someone else does something. As for my C# skills, well, I’m not proficient. I’m one of those, It may take me an hour, but I’ll get it, kind of guys.

@kjavid How would you switch it on? Sad to say, I never thought of an on off switch. We use the attachment sin Order Entry and Quotes, so I am familiar with the use of those. But, why maybe?

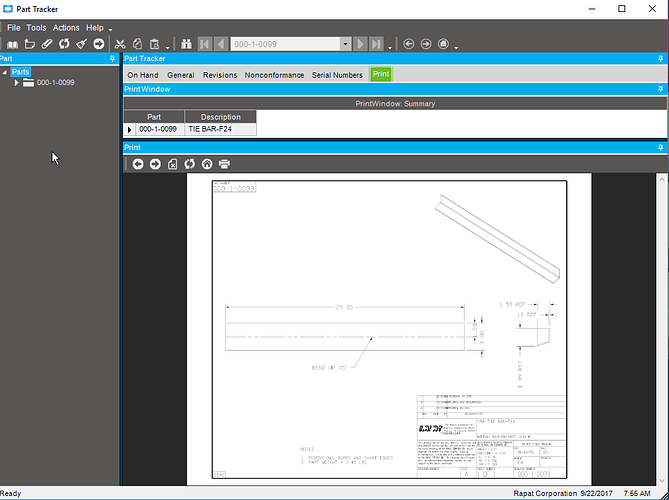

We have customizations in or engineering workbench and part tracker that goes and gets the PDF print for a part number to show for for parts. It’s the URL view in a dashboard, and you can insert that screen into an epicor screen using customization. If the naming convention of your resources and the file names of your pictures are such that you can build the file path using tokens, you can display it that way. No coding necessary.

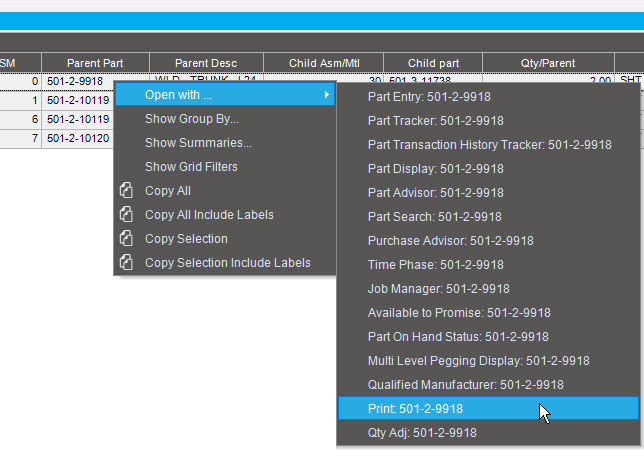

I just made it it’s own tab so it wasn’t in the way, but for whatever part you have pulled up, it goes and grabs the print. I also added the base dashboard to the context menu for part number, so you can right click in the part number and choose print, and it opens up the dashboard with the print from anywhere in the system displaying a part number.

I’m sure you could do the same thing for resource groups with a little work.

@Banderson That sounds promising. I know of the URL view, but I have not does any customization of my own yet. If this is a simple one, this may be a good place to get started.

My role here is to streamline our process and make them more efficient. I’ve already cleared up several inefficiency and now they want me to tackle this one that is causing substantial time waste for some people.

I’m gonna study and read up a bit. Do you mind if I ask more questins on this topic as I go through it? i like the setup I see and I think this will work. I’m assuming the Dashboard just basically sees the part number/resource number and then, using the local server, finds the corresponding print. Sounds easy enough. LOL!

Depending on how your users want to see it, the simplest way to make it easy to pull up would be to make the dashboard and add it to the context menu. (assuming the resource group has one, I haven’t checked but I think it does). Then there would be no customization necessary. The screen customization is a little touchy trying to get it to lay out right, so it can be kind of frustrating, but it can be done. The nice thing about the context menu is, it’s not in your way when you don’t need it, and it follows along with where you are clicked it you are looking through a list. Works nicely on two screens.

Here’s a link to how to use tokens to build up a path. This one specifically is going to the internet to get QR codes, but the premise is the same to go look for image files. If you can make the BAQ to look at your resource groups, then you can build up the file location using the tokens, or alternately you can make the location in a calculated field in the BAQ. Lots of options.

Yes - the work around will be a better option. Attachments is a flag that is switched on at the point of generating the b.o. So the system knows to include the framework code. Lots of downside to that solution I’m afraid. Also you will need sdk…

Our dies are identified as parts and therefore on the BOM (at a quantity of zero, they are not consumed). The dies are then issued to each job for tracking purposes (and returned to the warehouse when the job is completed). The print and pictures of the die is in the attachments of that part number.

Interesting. Very interesting. Have you had any issues with using it in this fashion? Would you do anything any different?

It works pretty well but we have not tried using a die as a resource so I cannot comment on which is better. We have over 5000 dies so using part seemed the best way, particularly since we inventory our dies in the warehouse and frequently use multiple dies per job. We can then have the warehouse kit our dies with the materials for a particular job.

Jim

![]()

We don’t have quite that many dies, but we do have quite a few. So, I will ponder this and maybe set it up in the test and see how that goes. Worth looking into.

Hi Will, the options users have suggested here are what would typically be recommended for your needs. If you want to attach an image without customizing, then the option to create a part and add it to the BOM (with quantity of zero) would be the best. Otherwise, the customizations mentioned would work well also. There are pros and cons to each approach. As a Resource, it would allow you to use it as a constraint to a schedule. As a part, you can track usage of each die (and/or other tooling). Hope this helps!