I cannot figure out why a part is automatically being checked for inspection. Does anyone know of the confs that could be causing this?

Thanks!

I cannot figure out why a part is automatically being checked for inspection. Does anyone know of the confs that could be causing this?

Thanks!

Unchecked

Also appears in Part Class…

Inspection Required

Indicates that parts assigned to this class must be inspected when you receive them into your shop. If you select this check box, when you enter a receipt for any part in this class, you will automatically receive it to inspection.

The supplier or the part class might be marked for inspection.

Vinay Kamboj

.

Neither Part Class or Supplier is marked for inspection. It shows up on the PO suggestion automatically.

So a PO generated from PO suggestions automatically sets that field?

Does a manually created PO for the same part do so too?

What is driving the suggestion? Min, Safety, BTO, BTJ?

A manual PO does not check it. Mins and/or Job demand drives the suggestions.

in this particular case, was it a Min or Job demand?

Anything special about that job? Like the “Inspection Required” box checked on the Material Detail?

one case is job demand. I did a query on job mtl for that part and all jobs with that material do not have inspect required checked.

From the filed help on PO entry

Important: You can also select an Inspection Required check box for part classes or suppliers. If this purchase order is for such a supplier or for a part in such a class, the Inspection Required check box is selected automatically, and it cannot be changed.

I know you said the supplier and Part class don’t have it set. But can you uncheck it on the PO?

If not, that would indicate that there is something driving it.

Does anything show up under the Lines → Inspection tab? Was an Inspection plan added to this line?

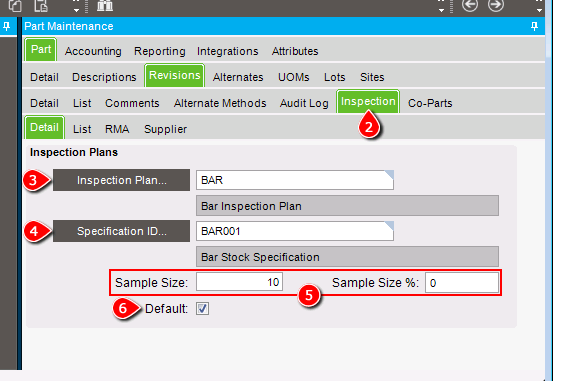

Another place to look is on Part Maintenance. Maybe someone added an inspection plan.

It is Revision specific, so make sure you’re looking at the right rev

nothing, i cant seem to find what is causing this.

So “Inspection Rqr’d” is being enabled ONLY when a PO suggestion is made into a PO?

Does it do to all parts, specific part (the same part always gets set), randomly (setting is inconsistent for the same part)?

Any BPM’s related to PO’s ?

Seems to be specific parts. No BPMs.

And the demand for those is always due to a Job requirement? Or are some just for Min / Safety stock?

If on a job, are they part of a BOM, or are the job details created “manually” (adding parts to the MOM as opposed to using Get Details). If using Get details, is it from a BOM, or a prior job(or quote) acting as a template?

Job req or mins.

Part of a BOM for job creation.

The PO created have other parts on it too? If so, do they all get the Insp Rqr’d box checked?

One part. One PO.