If we were to stop using MRP to suggest jobs to make from Sales orders what would we do instead?

Do you mean just stop making direct form SO or stop running MRP all together?

Hi John,

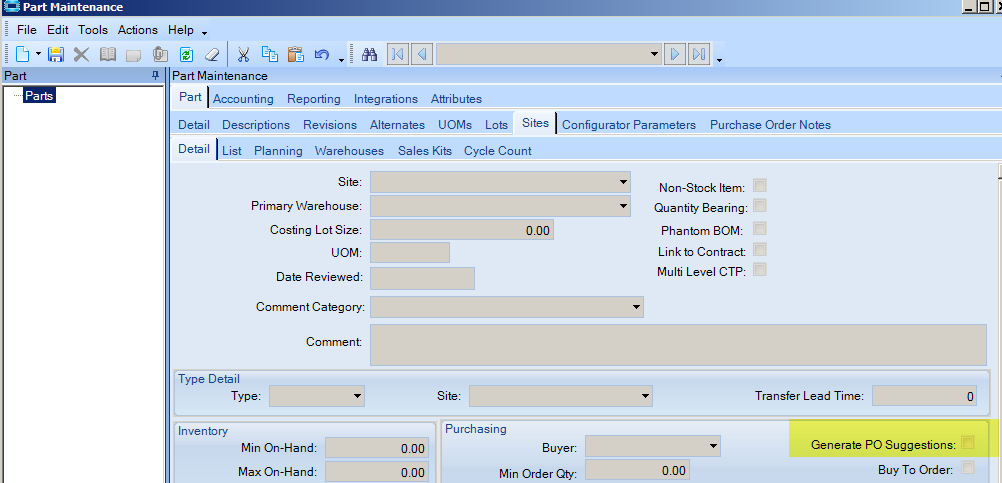

We do use MRP but also use Make Direct for jobs that we don’t want to run through MRP. For the latter, we check Nonstock on the part master, this makes it make direct on the sales order release. Also, on part plant planning tab we ensure Process MRP is unchecked. After that, when a user places one of these make direct parts on a sales order we see it as a new Planning workbench suggestion immediately, no need for MRP run.

Nancy

Stop running the MRP altogether, is there anything else that would suggest we need a job?

We don’t run MRP. We use the Job Manager.

Open Orders Report shows us which things need to ship. If an order line item is make direct (90% are), a job needs to exist for that item.

Job Manager shows shows the supply and demand for a part, as well as all the links (which job is for which demand, etc…)

EDIT: All our BOMs and MOM’s are single level. We do have some sub assemblies. But those are stocked, so a sub-job isn’t created.

See what @ckrusen says… it depends on what you mean by “suggest”. If you don’t run MRP, someone will have to manually look at the reports he mentions to see what is needed, and then manually create the jobs to product them.

I like the planning workbench. You can search for all new suggestions and mass create, get details, schedule and release make direct jobs. The workbench shows the SO line release, and you can pick and choose which ones you want to make jobs for.

The suggestions are created as soon as the SO release is created. No need to run any generate processes.

Hi Nancy,

This sounds like something we could use, what happens about the raw materials that are required on these jobs? Do you get purchase suggestions if there is no stock? Or do you have manually check each job?

Thanks,

John

We don’t use MRP, and PO suggestions are created. (Assuming you run the process to create the suggestions)

anything else that would suggest we need a job

Maybe the “Time Phase Material Requirements” and “Stock Status” reports?

Depending on the volume of demand/supply, might be able to develop your own “manual” MRP process.

e.g. review demand/supply info in report(s) and manually create jobs as needed.

Hi John,

Yes, you will get PO suggestion for the materials if: you created a job from the new planning suggestion, you placed or pulled method details to have the materials on the job, you schedule the job (must be firm too, naturally is this from changing a suggestion into a job), the job materials are setup as purchased type in part master and have generate suggestions checked on the plant tab.

Nancy

Releases with “Make Direct” = true use Job Manager.

Releases with “Make Direct = False for manufacture parts “Non-Stock” = false use “Time Phase Material Requirements Report” select Exceptions Only / Below Zero.

Sincerely,

Patrick Winter | Information Technology Manager

2801 Huffman Boulevard | Rockford | IL | 61103 | (815) 969-4147